Research Team led by Prof. Yu-Hsiang Hsu Develops Novel Lab-on-a-Chip System for Microfluidic Mixing

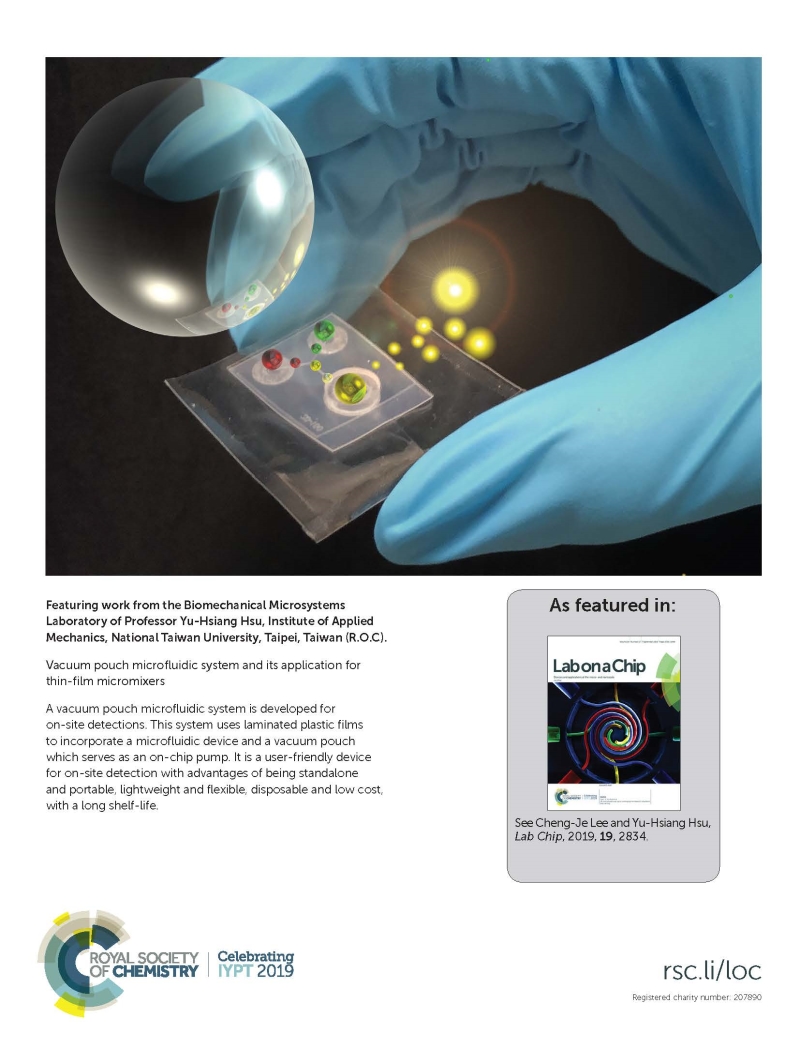

Prof. Yu-Hsiang Hsu (許聿翔) and his doctoral student Cheng-Je Lee (李承哲) of NTU’s Institute of Applied Mechanics developed a lab-on-a-chip system called vacuum pouch microfluidic (VPM) system, which can be applied on thin-film micromixers. Hsu and Lee were inspired by the design of vacuum bags, and their research was selected for the cover of the September issue of the Royal Society of Chemistry’s Lab on a Chip, a high-impact journal for microelectronic biomedical research.

Applying microfluidic methods has become a trend in biomedical, biochemical, and environmental monitoring research. Despite abundant literature, few microfluidic chips have been successfully commercialized, and most mature microfluidic products on the market are test papers that rely on capillary force. Over the past decade, scholars have tried to figure out why microfluidic devices are not so popular. The research revealed that building a high-quality world-to-chip microfluidic interface is the key to increasing the market penetration rate of microfluidic devices.

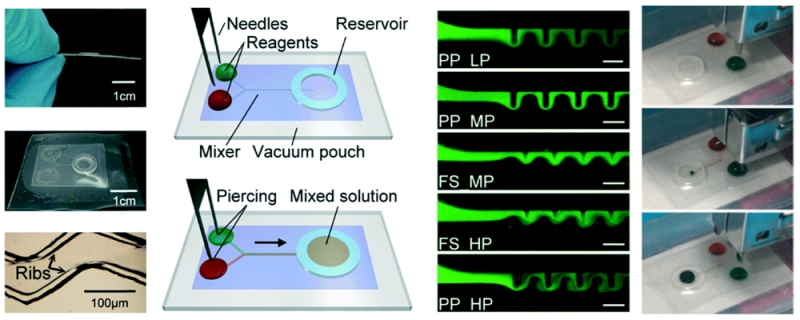

Hsu and Lee used a commercial hot embossing process to fabricate a thin-film micromixer. Then, they laminated a degassed plastic pouch with the thin-film micromixer to develop the film-type self-driving VPM system that is only 0.4 mm thick and 0.3 g in weight. The operation of this VPM system is also significantly easier to perform than are conventional methods. Users only have to load the reagent and analyte to the system, pierce it with a needle, and release the negative pumping pressure stored in the vacuum pouch to complete the mixing process. The study also verified the feasibility and reliability of the system by applying different chip designs and solutions. Information on how long the VPM micromixer can be stored and the possibility of its commercialization are also discussed in the study. Lee is positive about the potential of this technology, as it only takes a plastic thin film and atmospheric pressure to adjust over a thousand variations of microfluidic speed changes.

The researchers used an efficient, simple strategy to construct a microfluidic system that is standalone, portable, disposable, lightweight, and low-cost. Moreover, the micromixer can adjust solution and volume flow rates in the channel to perform different mixing tasks. Meanwhile, this research team is actively applying this technology to more microfluidic practices, such as multiphase flow and particle filtering, hoping to develop an integrated, portable personalized biomedical testing platform for rapid screening and on-site medical services.