NTU and LANL Develop a New Approach for Producing High-performance and Robust Perovskite Solar Modules

Prof. Leeyih Wang (王立義) of the Center for Condensed Matter Sciences leads an international research team with members from NTU and Los Alamos National Laboratory (LAML). The team has developed a new synthetic route that breaks the bottlenecks and opens the way to prepare large-scale, high-quality organic-inorganic hybrid halide perovskite. This innovative new approach enables the fabrication of robust, highly efficient perovskite solar modules. This research result was recently published in Joule, a renowned journal in energy studies.

During the past decade, unprecedented progress has been made in pursuing high-efficiency perovskite solar cells. Recently, a single-junction perovskite cell with outstanding power conversion efficiency was selected by the industry for potential commercialization. However, two barriers to commercialization remain, namely, the lack of low-cost and scalable production and poor device lifetime. In other words, a scalable fabrication approach that yields a durable, high-quality perovskite layer over module scale is the key to making perovskite photovoltaic technology commercially feasible.

Ph.D. student Hsin-Hsiang Huang (黃信祥) of the Department of Materials Science and Engineering (left) and his dissertation advisor, Prof. Leeyih Wang of the Institute of Polymer Sciences and Engineering (right).

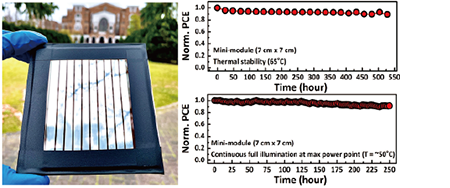

This study identified sulfolane as an additive in the perovskite precursor that converts perovskite phase via a new reaction route. The key issue lies in building intermolecular hydrogen-bonding forces between sulfolane and methylammonium iodide, which would slow down the nucleation and crystallization process and significantly extend the processing window from 9 to 90 seconds. Importantly, two mini-modules have PCEs of 17.58% and 16.06%, respectively, and the encapsulated mini-modules retain about 90% of their initial performance after operating under 1-sun irradiation for 250 hours at 50℃.

The leaders of the LANL group, Prof. Leeyih Wang and Dr. Wanyi Nie, point out that broadening the processing window in the antisolvent route is essential for transferring the process to industrial-scale production. It allows the flexibility in up-scale process development without sacrificing device performance. The large-scale production can also benefit from the widened time window for better tolerance towards manufacturing errors and environmental variations. This work paves the way for low-cost, high-throughput commercial-scale production of large-scale solar modules in the near future.

A perovskite solar module and its operational stability.