Research Results of “Spray-coating Process for Perovskite Solar Cells Application” Selected as the Cover Page of the ACS Applied Energy Materials

This cover page highlights a study on a spray-coating process for perovskite solar cells application by Prof. Cheng-Liang Liu’s group from Materials Science and Engineering of NTU.

Perovskites have emerged as revolutionary optoelectronics used in various devices, including semiconductors and photovoltaic cells. Extensive research has revealed that laboratory-scale solar cell performance largely depends on the quality of the perovskite crystals used. Most of the cells were manufactured via spin-coating, and this deposition method is not scalable for high throughput manufacturing and future commercialization. Spray-coating is a promising scalable alternative where the precursor solution is ejected through a nozzle, aerosolizing the solution. To that end, our group has been at the forefront of spray-coated perovskite layers for solar cell applications, with recent contributions, including (i) ChemSusChem, 2017, 10, 1405-1412 (simultaneous growth from precursor; one-step method). (ii) J. Power Sources 2018, 390, 270-277 (sequential growth from precursor; two-step method). (iii) ACS Appl. Mater. Interfaces 2018, 10, 38042-38050 (large active-area device). (iv) ACS Sustainable Chem. Eng., 2019, 7, 14217-14224 (mixed cation perovskite). (v) Energy Technology, 2020, 8, 2000216 (fully spray process). (vi) J. Power Sources, 2021, 491, 229586 (mini-module) (vii) Adv. Mater. Interfaces, 2021, 9, 2001509 (multi-channel precursor pumping system). (viii) ACS Appl. Energy Mater. 2021, 4, 5466 (All-inorganic perovskite). (ix) Solar RRL, 2022, 6, 2010135 (Review on progress in spray-coated perovskite film for solar cell application).

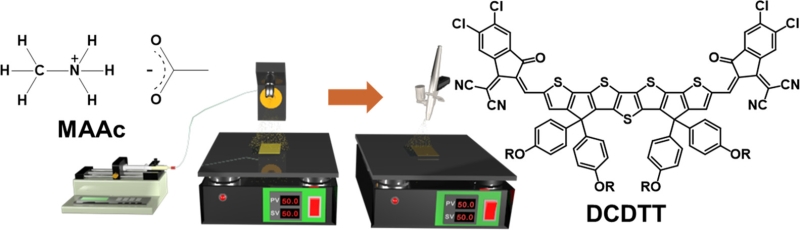

Due to the nature of solution processing and the rapid crystal growth of perovskite thin films, various defects can form as a result of precursor compositions and processing conditions. The use of additive engineering can affect the perovskite crystallization, film formation, defect passivation, and interface tuning for efficient and stable perovskite solar cells. This work demonstrates improved photovoltaic device performance and stability using methylammonium acetate in the perovskite precursor solution and a nonfullerene fused-ring dicyclopentadithienothiophene-based small molecule (DCDTT) during the antisolvent step as synergetic additives for the ambient fabrication of a perovskite film by an ultrasonic spray-coating method. As a result, an inverted perovskite solar cell treated with additives achieves a significantly higher PCE (17.18%) than the untreated device (10.04%) and retains ~85% of the initial PCE after 7 days under ambient conditions. The obtained PCE of our device is one of the highest efficiencies among spray-coated MAPbI3-based planar perovskite solar cells.

Contact Information:

Prof. Cheng-Liang Liu

liucl@ntu.edu.tw

Schematic illustration of a completed device structure, where the perovskite film was prepared by ultrasonic spray coating. The MAAc additive was introduced in the precursor solution before the coating process. The DCDTT–chlorobenzene antisolvent was sprayed on the as-fabricated perovskite film.

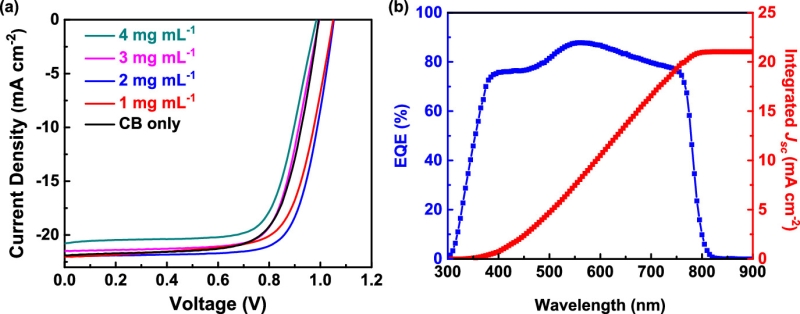

(a) J–V characteristics of MAAc (X = 1.5)-doped perovskite solar cells fabricated by antisolvent additive treatment with 0, 1, 2, 3, 4, and 5 mg mL–1 of DCDTT in chlorobenzene. (b) EQE spectrum of the best-performing device fabricated by antisolvent additive treatment (2 mg mL–1 of DCDTT–chlorobenzene).